The design process starts simply enough – an observation, a challenge, a problem – it’s an opportunity to make something … or maybe it’s just making something better.

See a need, fill a need. Make something. Make something better.

That’s how I start every design process, although, I have no doubt that everyone has their own similar path and process that they follow. Every year for the past 6 years, I have been following this process, designing and donating playhouses to a local charity that does good things – a group that makes things better. I do this because I can, and because of this, I found myself this past holiday weekend up at the office preparing construction drawings for the playhouse I designed this year.

The sketch above is one of the very first ones I created when I started thinking about what sort of playhouse I would design this year. Pretty simple sketch and idea, but make no mistake about it, these playhouses can be deceptively complicated little buildings – at least they are the way I do them. Despite having a fair amount of experience under my belt, these itsy-bitsy, teeny-tiny structures take an exorbitant amount of time to properly design and detail despite how simple I try to make them appear.

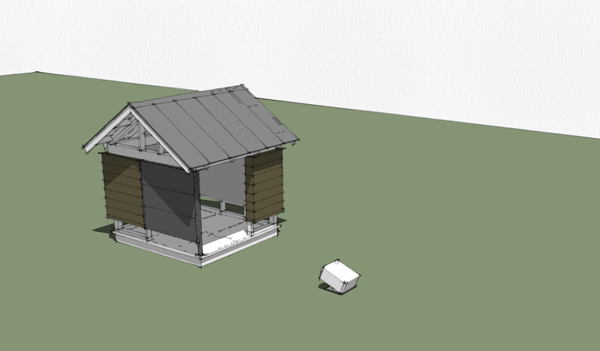

A few weeks ago, I showed you the images I made of this years playhouse design, titled: ‘The Outdoor Movie Theater‘. When I compare the concept sketches to the finished design, I’m pretty happy because the final product is still a fairly true version of the original vision.

Since I host a playhouse design competition on my website, I tend to go through a similar unveiling process every year. What does that actually mean? Well, because I get people sending playhouse designs, I have to make sure that my design is finished and presented before everyone else sends in their entries – I do not want to be accused of “borrowing” from someone else’s design. As a result, I always publish my design here for everyone to see – you can see that post, which shows all the concept sketches and the 3-dimensional images here: Outdoor Movie Theater – 2015 Playhouse.

The next step in the unveiling process is that I publish the construction drawings for my design. I have shared the construction drawings for every playhouse I have ever designed … for FREE (you can find them all here). All you have to do is take them down off the Life of an Architect website and you are good to go. All I ask in return is that you send me some photos of the finished playhouse.

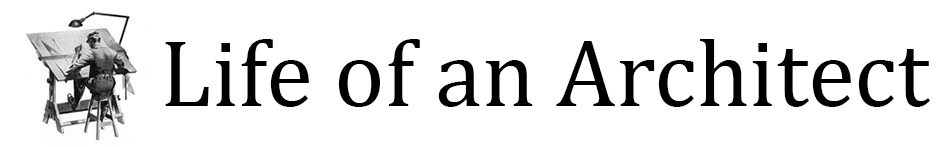

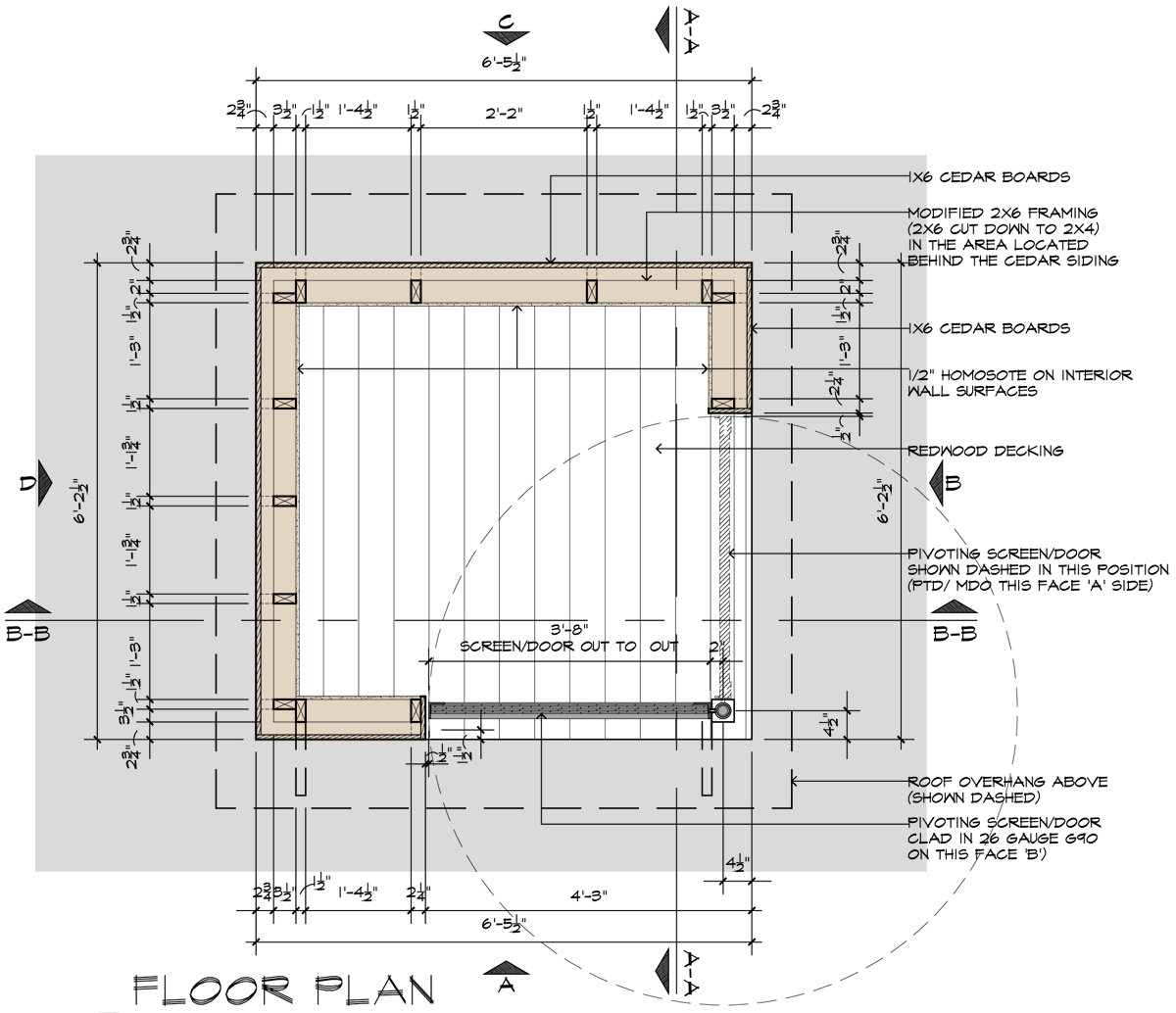

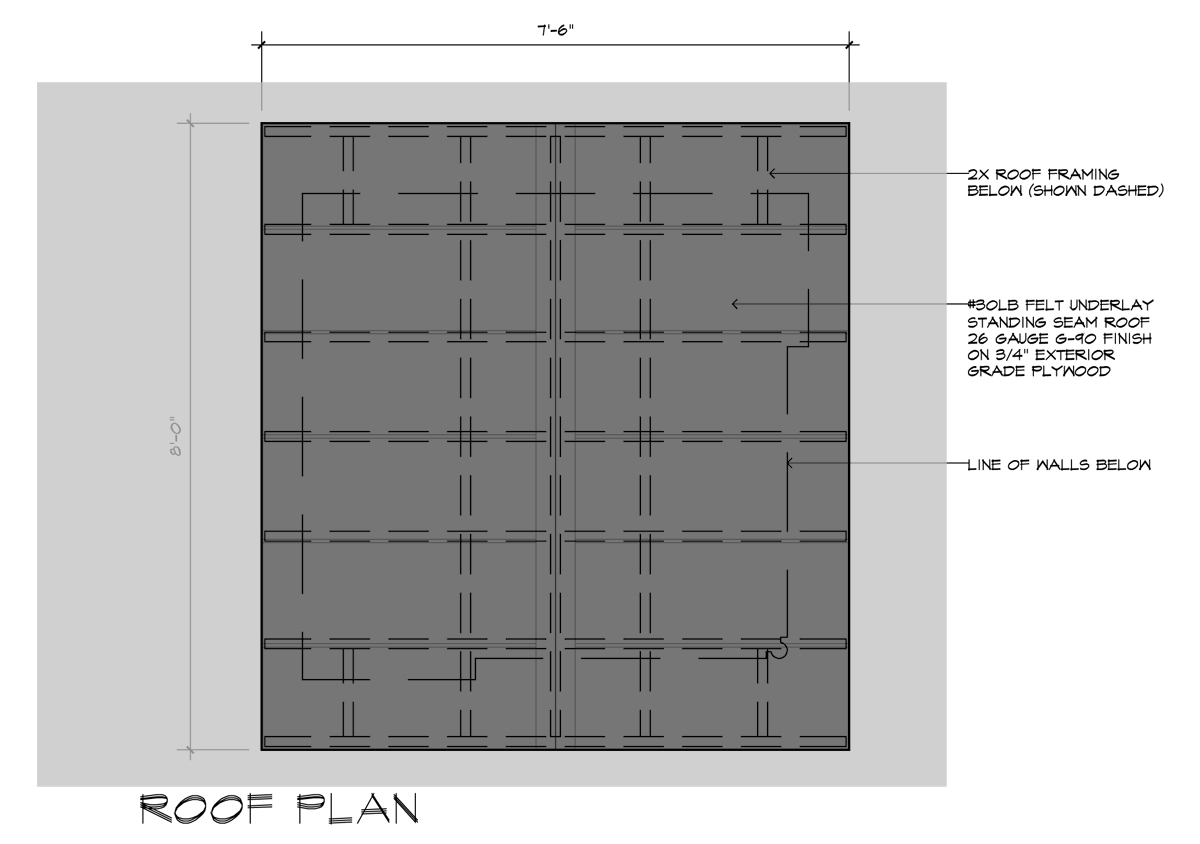

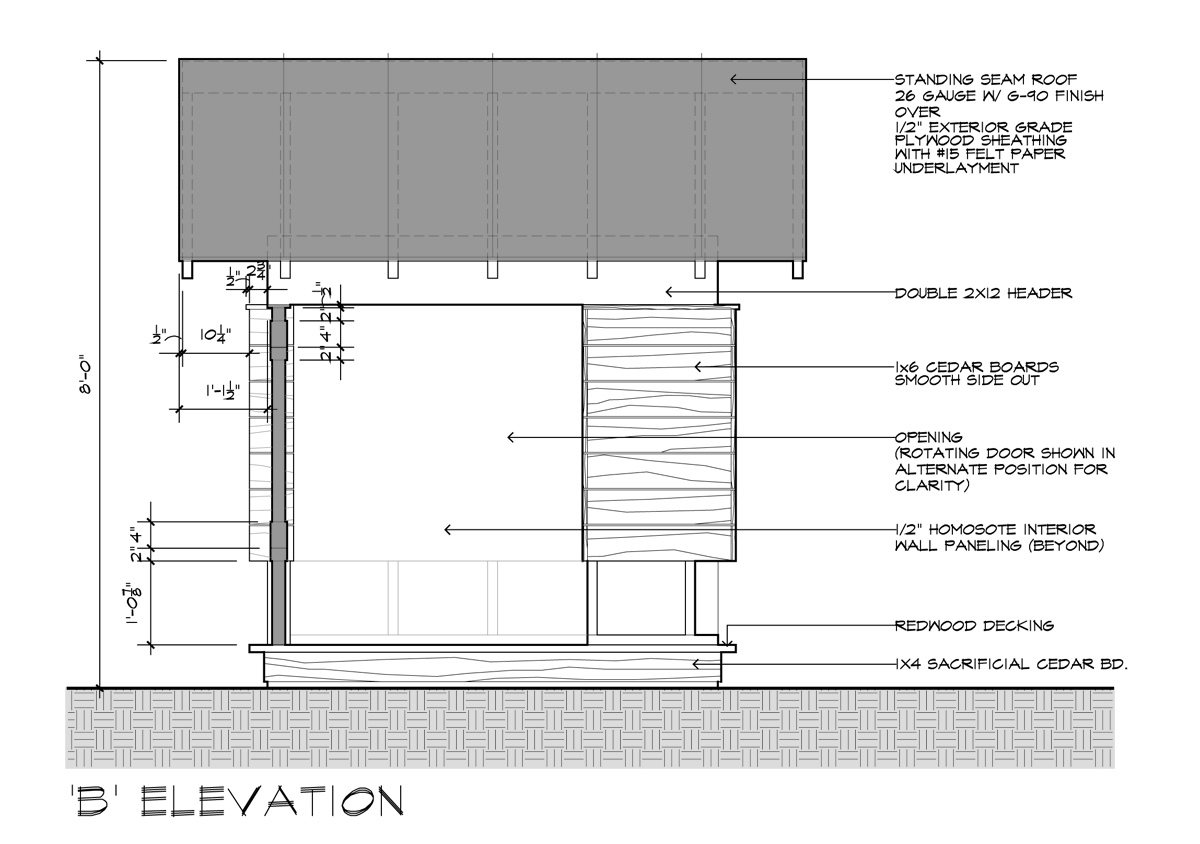

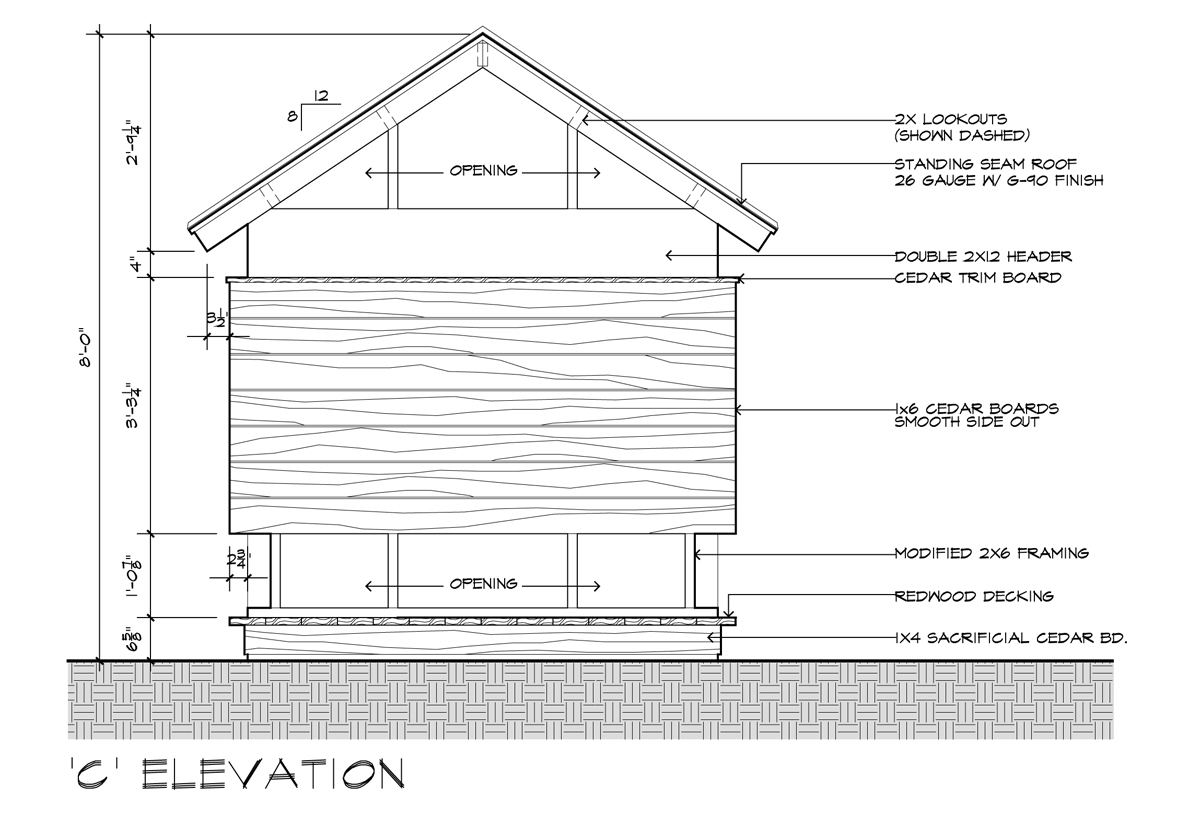

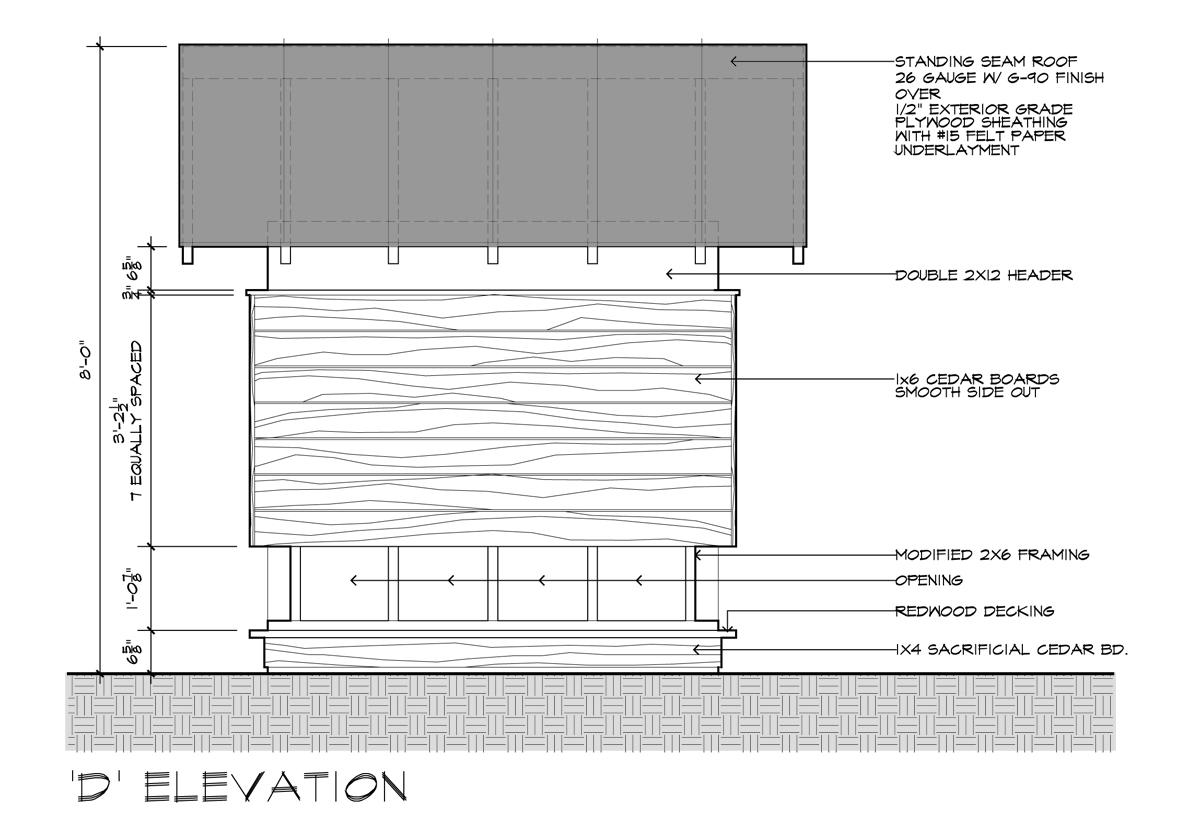

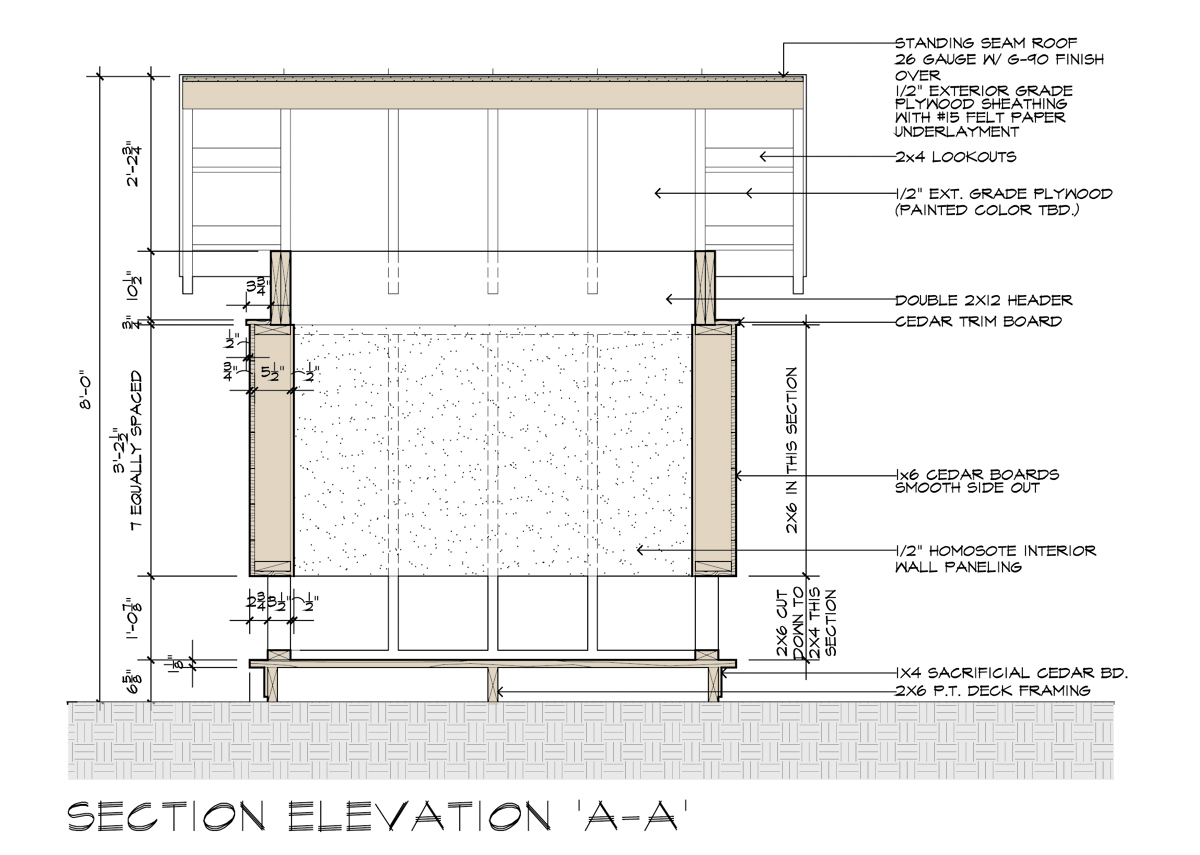

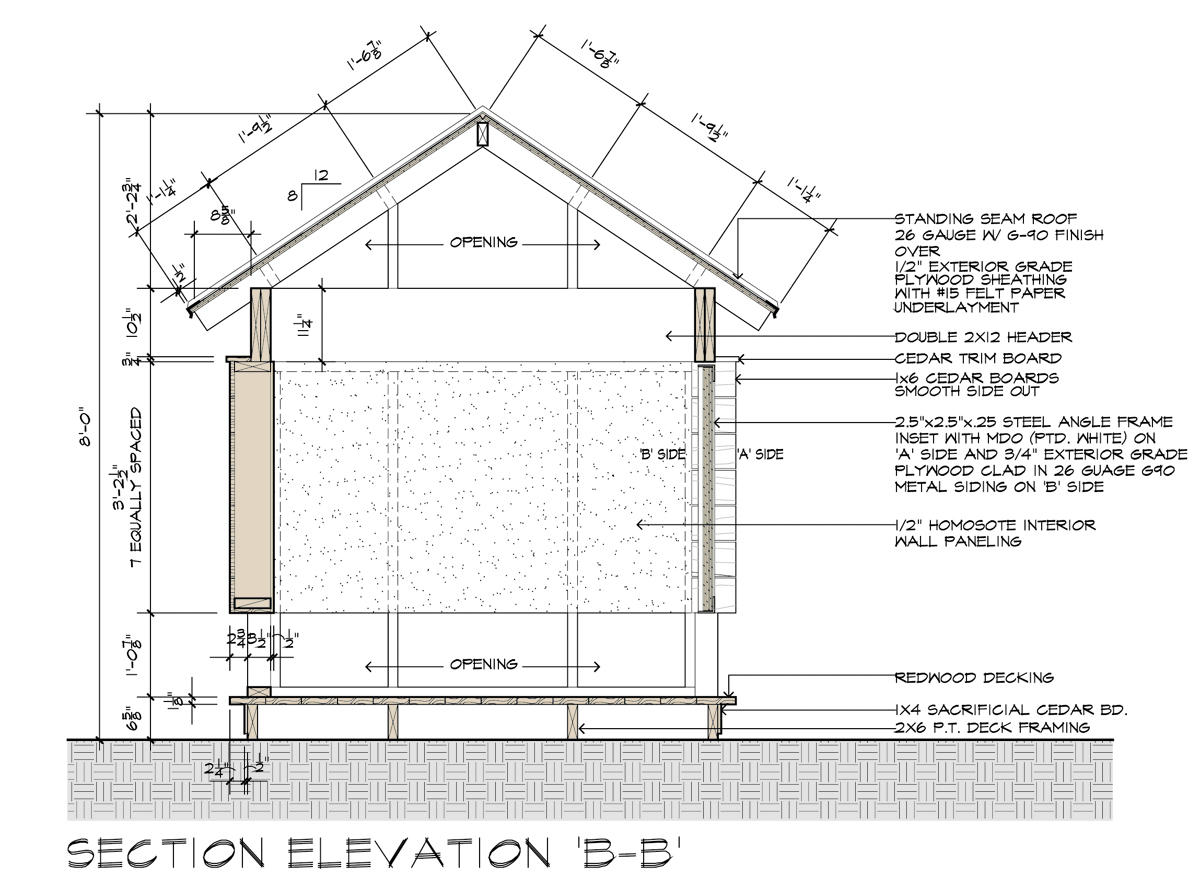

Each one of these drawings can be clicked upon and a new window will pop up with the drawings twice as large as you see them here. I get a lot of requests for people to email me the drawings because they can’t read the dimensions in the smaller images – all of these are individual images that are easily legible if printed out on 8 1/2″ x 11″ paper.

I should confess that my wife and daughter went on a retreat this weekend so I found myself with a lot of alone time … which I don’t particularly enjoy (I can be exhausting). Normally when I find myself with a little spare time, I tend to park myself on the couch and cue up as many movies as I possibly can (which for the record, is a lot, a fact that I am not very proud of).

But not this weekend. This weekend I decided (after looking at my calendar for the next 2 weeks) that I had better get these construction drawings done. How long could it possibly take to prepare construction drawings on a structure that is barely more than 40 square feet?

This year, the answer to that question is 10 hours.

I have found over the years that the construction drawings I prepare for my playhouses reflect the design process itself … I draw everything. I don’t normally dash in the studs beyond … for that matter, I don’t normally draw and dimension stud placement. Accuracy and thorough communication is really important here because there isn’t any wiggle room in these designs. I draw and dimension where the stud goes because that’s where I want the stud to go. Things like scale, alignment, proportion – you know, architectural type things – are important, and rather than whip these drawings out so that I can get home and watch some movies, I like make sure that the time I’ve spent aiming for “scale” and “alignment” are actually represented in the construction drawings. The result is that I tend to stick way more information than might actually be required into these drawings – almost to the point that the drawings start to get hard for anyone to decipher unless they bring their ‘A’ game.

Good thing I have an ‘A’ game contractor building it! BufordHawthorne Homebuilders has built a playhouse for me every single year since I started designing them, so they have a good idea of what is coming.

There are still some things I have to resolve – in particular the pivoting steel support that holds the “movie” screen. I have a pretty good idea how it will be done but I would like to get the actual guy who will be making it involved – they might have an idea that’s better than mine (you know, since they do this sort of thing every day). The whole assembly is basically (on the non-movie side), G-90 metal cladding on 3/4″ exterior grade plywood; then a 3/4″ layer of one-side MDO exterior, grade B-C (painted white), all of which sits in a 2.5″x2.5″x1/4″ painted metal frame that is cantilevered of a 2.25″ steel tube.

*Don’t know what MDO is? You should – it’s awesome stuff. Read this : Exterior Ceilings – Here’s an Idea for You

Elevation ‘B’ is the movie screen side – looking at the opening above, you’ll see the location of where the white-painted MDO side of the pivoting door would be if you wanted to watch a movie out in the yard. Of course, you could leave the door in its other position if you wanted to watch your movie from inside the playhouse.

The bottom is completely open in this playhouse – well, at least 12 7/8″ inches of it are – I have a “proof of life” requirement in all the playhouses I design. This means that when children go inside the playhouse, the person responsible for making sure those children are doing well in the playhouse can actually see them moving around. It also allows for air movement through the playhouse – another item that is pretty important since it gets hot in Texas.

This is about as close as you are going to get to a “back” elevation. Since it is on the opposite side of this playhouse from the movie screen side, this is the side that would be the least seen …

But that doesn’t mean I want it to suck.

These section elevations are probably the most valuable drawings I prepare on these playhouses. These show the interior of the playhouse and the wall section – the part that really discusses how the playhouse is to be built.

Out of all the playhouses I have built, I’ve only used “Homosote” in one other design – a Japanese themed playhouse I designed back in 2010 (which also remains one of my most favorite designs). You can see the images here and see how the homosote was used. Homosote is basically a pressed paper panel that is unfamiliar to most people – we used it extensively in college to tack up drawings. Since the walls won’t actually get wet, I’m not overly concerned about using a compressed paper wall board as a finished material. Besides, if after a few years the lucky owner of this playhouse wants to replace it, they will only need to buy three 4’x8′ panels, and a panel only costs around $25.

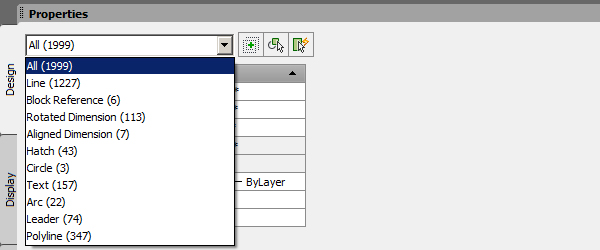

Finally, I thought it might be interesting to see some technical information associated with these construction drawings. I have already confessed that it took me about 10 hours to prepare these drawings -I don’t know if that sounds like a lot or a little to the brave souls who have actually read this entire article. I went relatively old school and did them in AutoCAD since I am still more familiar with AutoCAD than I am with Revit . When I was done, I did a screen grab of all the drafted items within these drawings – you can see them listed in the image above. There are only 1,999 items in these drawings – What?! I would have bet you a LOT of money that it would have been closer to 10,000 items. That’s only 10 things every 3 minutes!!

Does 1,999 items sound like a lot? Who knows, but I’m pretty sure that I needed every single one of them.

Cheers,