Being an architect isn’t as glamorous as you might think – at least not all the time. I generally work on single family residences and most of these houses are modern in style. During a typical day I spend a fair amount of my time designing – and coordinating those designs – so I think I have it pretty good. Part of the reason I think I have found happiness in my chosen profession, despite being pounded with emails from people who think being an architect is currently a terrible idea, is the attitude I bring towards my job. Not everything I do is big picture design – compared with the overall time spent, very little is – but I consider coordinating a project and the details of the construction of that project integral to a successful design.

There are many things I do during a typical day – designing “stuff” is just one very small portion – but I still consider myself a designer more so than a project architect. Since I work at a smallish firm, everyone wears many hats and nobody has just one task or label. To be considered a designer just means you need to think about the design of everything – and I mean everything. I have said on many occasions that it is the little things that matter in modern design so despite the fact that I spent the first part of my morning coordinating the fire sprinkler heads, all the penetrations in the ceiling plane will align, that is still designing. That might not sound like much but there is a lot going on in the ceiling – light fixtures, sprinkler heads, air supply and return grills, security sensors, audio speakers – and it all has to be coordinated with where the air-conditioning ducts are running, while missing all the structural beams. I design details as well as buildings.

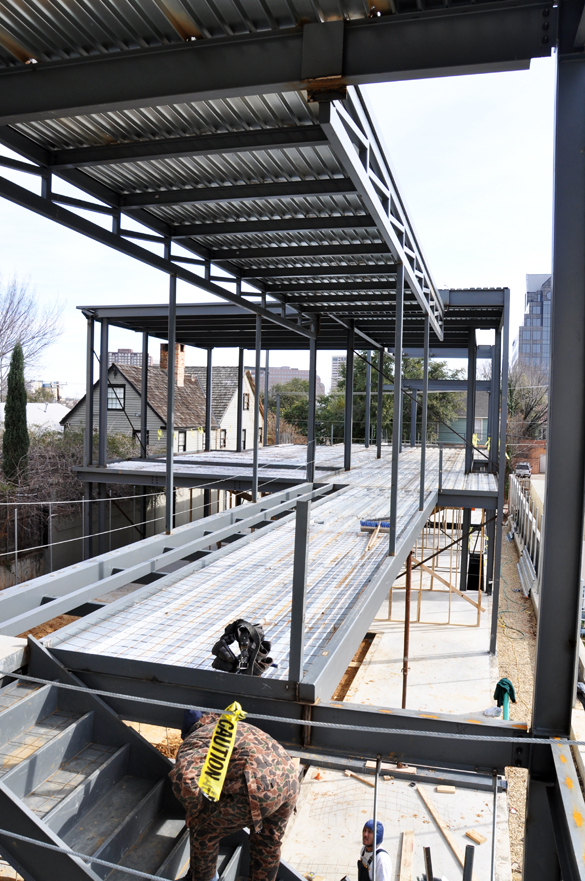

I did a walk-through on the site today just to document progress and thought I would use the bridge in the project as an example of what I am talking about. Let’s start with the site photos:

.

From this angle, we are looking up at the bridge connecting the building at the front of the lot to the building at the rear of the lot. The stage of construction at this point is that most of the steel structure is in place and the contractor is pouring floor slabs. The steel for the bridge went up last week and the metal fabricators are on site installing the stairs. I am standing in what will be the interior courtyard of the building and the side of the bridge facing me is almost entirely glass – from the floor to a height of 10′-0″ and the span is 40′ between the two building masses.

.

This is a view from the upper level looking down the bridge. That is one of the steel-workers if you are wondering what that camouflaged blob is at the bottom of the picture. To minimize the visual weight of the bridge, we brought the glass down to the floor and we are running all the mechanical and electrical in the ceiling above. This allowed us to reduce the depth of the floor to just about 16″ – which won’t look like much for a 40′ span.

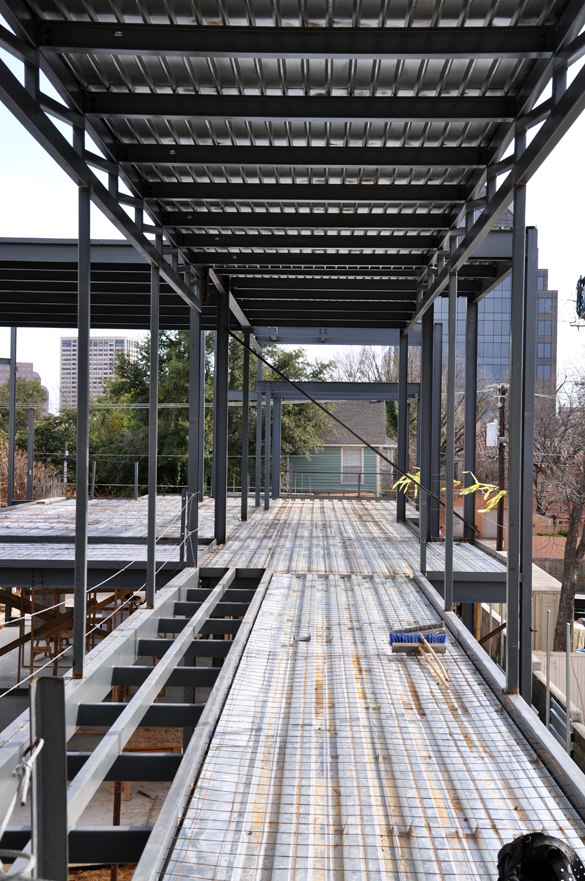

.

This is an important shot to convey the intent of today’s post. On the right hand side you can see the metal decking and welded wire mesh where concrete will be poured for the floor of the bridge. The repeating rectangular spaces on the left will remain visually open – we are installing a glass floor along the length of the bridge. The steel members will actually become the support for the individual pieces of glass – which do have size limitations. This is how we determined the spacing of the structure … based on the glass limitations. The joints in the floor between the individual pieces of glass will also align with the glass that will be in the wall.

.

.

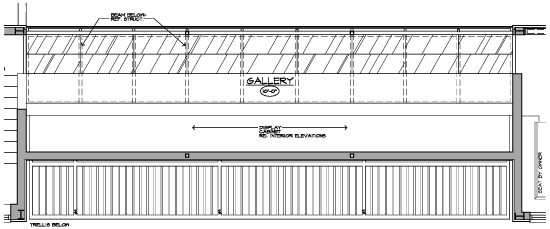

I know that not everyone reads construction drawings so if you don’t I apologize in advance. I included this partial construction detail to help show the relationship between the floor (both the glass and concrete portions) to the overall bridge shape.

.

Here is a enlarged look at the corner of the bridge walkway where the glass floor and the glass wall come together. The arrangement and sizing of the structural steel was worked and re-worked until we got it to this point. There is enough of an offset with the steel beam so that the glass at the floor has a place to set. We also sized the vertical columns that connect the structure at the floor to the truss structure at the ceiling with 2″x3″ tube steel so that the width of the members could be enclosed within the metal of the window system. When this bridge is finished, you won’t see any of the columns in the glass wall.

So maybe it isn’t apparent but the point I am trying to make is that the design idea for this bridge took very little time to develop when compared to the development and coordination of the construction details. There is a lot going on but none of that should come across in the finished product – not if I’ve designed it well. So many phone calls … from the glazing vendor to talk about glass spans, to the structural engineer to convey my ideas on how this bridge should be framed, to the zinc manufacturer to coordinate how we wrap it in the zinc metal siding (did I mention that the zinc is black?) so that the material breathes properly. It all comes together and with the combination of design ability and construction knowledge of how things actually get built …

how could you do this and not consider yourself a designer?

.

People don’t always understand what we do or why we do it – and for the most part I am okay with that. I am the expert and that’s why they have hired me … so they don’t have to know about everything that’s involved. Their appreciation when it’s done tells me that I did what I was supposed to do.

.

.